Not long ago, plastic was considered king

In the sense that nearly anything and everything was made from some type of it. It was (and still is in many cases) the standard for shopping bags, toys, furniture, totes, and countless in-betweens.

Time has passed, and society’s sentiment has changed regarding sustainability and the lasting impact of plastic products on the planet. So, too, has the idea that plastic is the end-all-be-all in the field of manufacturing.

Now, alternatives are front and center as companies reassess their sustainability goals and environmental commitments. Companies like AirBoss — which specializes in custom rubber compounds and innovative products — believe they are uniquely positioned to deliver high-quality alternatives that make their plastic counterparts look like relics.

Why Rubber May Be Better than Plastic

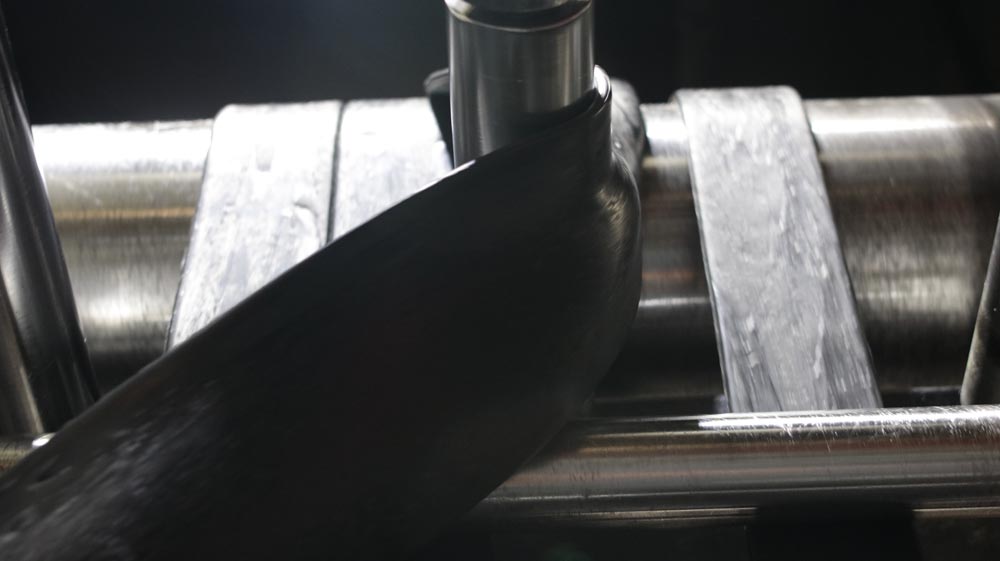

When taken to a microscope, both are a combination of polymers and additives that combine to create the final product or compound. As such, they’re both materials that can be melted, mixed, and molded into numerous shapes to serve various purposes.

Traditionally, their unique properties are what set them apart, but more and more, it’s these same properties that elevate modern rubber products above their plastic counterparts.

Tensile strength: While modern manufacturing plastics can have properties that are rubber-like, they don’t compare when it comes to the dialed-in adaptability rubber compounds provide. Long-used processes like vulcanization and more modern innovations like highly customized compound mixtures allow rubber products to vary greatly in preferred tensile strength.

Temperature tolerance: Again, modern plastics are designed to withstand greater heat variations than traditional mixtures, but most commercial plastic products are limited when it comes to extreme heat or cold. Many plastics soften and melt under extreme heat or become brittle and break when cold. Rubber, conversely, can have much higher temperature tolerances and can often retain its shape, toughness, and other properties even when subjected to a wide spectrum of temperatures.

Biodegradability: Sustainability will always be a consideration for modern manufacturers like AirBoss, and the result is a company priority to pursue more proactive sustainability goals. While efforts are being made to make plastics more eco-friendly, the history of plastic biodegradability is not a positive one. Some traditional plastics like bags and disposable diapers won’t break down for 500 to 1,000 years. Rubber, on the other hand, (especially natural rubber) is biodegradable and breaks down in about a year’s time. More chemical-heavy synthetic rubbers take longer to break down but are still highly biodegradable compared to plastics.

These are just three examples of why rubber can outperform plastics in most common applications, but the advantages of rubber products, compounds, and production processes continue to make it a preferred alternative around the world for certain applications.

Contact Our Global Experts

Learn more about how we can make a material difference in your business, contact our world class staff for more detailed information.

Rubber Products Perform Better and Cost Less in the Long Run

“But plastic is cheap and easy to work with,” a proponent might argue when asked why it’s their preferred manufacturing material. And they might be right.

For various purposes, in certain applications, plastic might be the preferred material of choice. Most plastics are less expensive than the more resilient, higher-quality rubbers, and many manufacturers choose quantity over quality when considering their bottom line.

What companies like AirBoss and our high-value clients understand is that plastics just don’t perform like rubbers do. Plastic hoses get brittle and crack while rubber hoses generally retain their supple durability. Rubber molded products like bushings are more effective when it comes to noise and vibration dampening, temperature tolerances, and their performance under high stress. The list of benefits goes on and on.

For these reasons and the inherent properties of more advanced rubber compounds, our customers choose the long-term benefits and cost savings of rubber over plastic.

Rubber Market Forecasts Continue to Look Promising

As mentioned, plastics and rubbers serve their respective purposes. For different applications, at different price points, one material may be more viable for a project than the other. That said, we at AirBoss recognize that rubber compounds, products, and production processes can provide unmatched reliability in specific specialized use cases that plastics just can’t.

And the global market tends to agree. Despite supply disruptions and uncertainty, it’s estimated that the global synthetic rubber market will grow to $23.2 billion by 2026.

As industries like electric vehicles and advanced automotive systems emerge, AirBoss is primed to put our expertise to use in enhancing what rubber can do today and tomorrow.